SQS Main Products Overview

- » Fiber Optic Bundles

- » High Power Laser Beam Delivery Cables

- » High Power Laser Diode Drivers

- » Microlens Fiber Arrays

- » Mini Fiber Optic Jumpers for Photonic Integrated Circuits (PIC)

- » High Pressure and Vacuum Optical Fiber Feedthroughs

- » Planar Components (PLC)

- » 1D and 2D Fiber Arrays

- » Special Fiber Optic Jumpers

- » Custom Fiber Optic Assemblies

- » High-Precision V-Groove Fiber Arrays

- » Light Emitting Diodes (LED) with Integrated Lenses

- » High-Precision Mechanical Parts (Development, Prototyping, Micromachining)

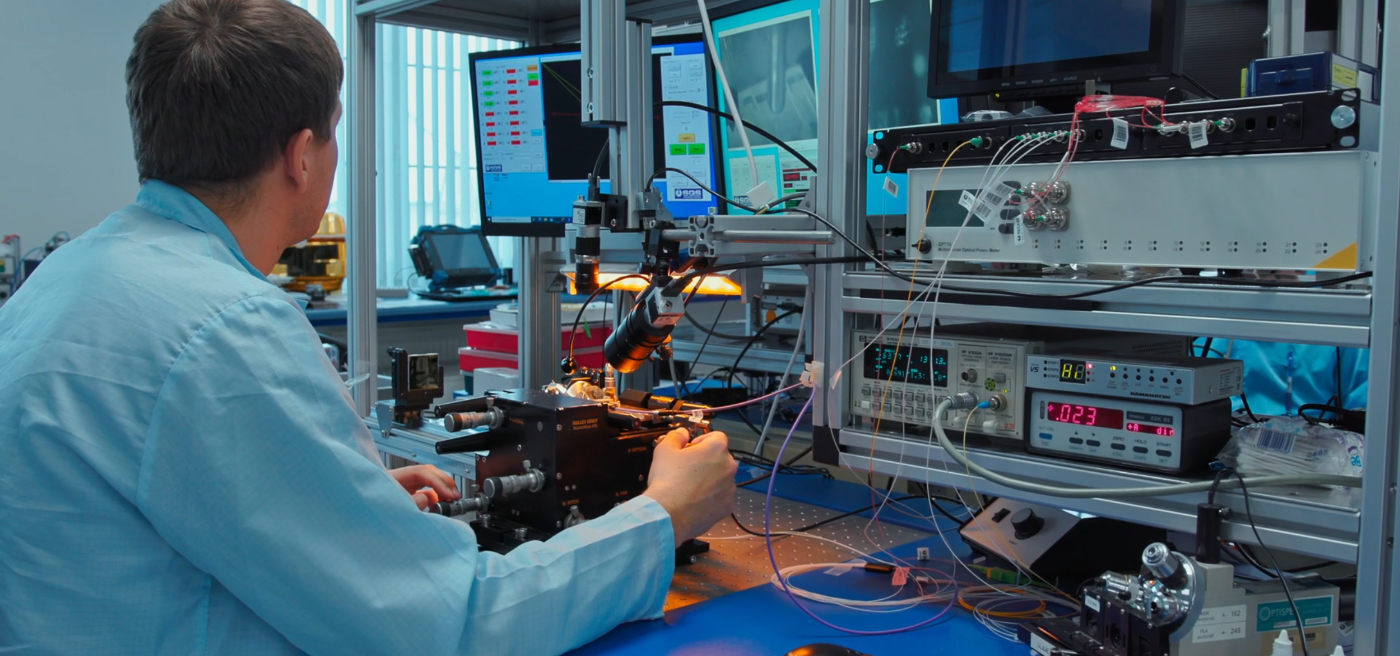

SQS Vláknová optika is a manufacturer of fiber optic, laser technology and optoelectronic components. SQS production is largely based on in-house development which focuses on innovations and new product development. SQS belongs to the leading companies in the market of fiber optics, and photonics in general, mainly in the field of custom based development and production of specific components for applications in various devices and systems used across industrial sectors. SQS products are often a combination of solutions from the fields of fiber optics, optoelectronics and high-precision mechanics.

SQS products are an important part of higher units, devices or systems working with optical signals. Besides conventional telecommunications and data transfer networks, SQS products find their applications across industries incl. the automotive, mining, engineering, chemical, medical and aerospace industry, submarine telecommunications and other sectors.

SQS products are mainly intended to customers who need high-precision and highly reliable solutions for their applications in the fields of fiber optics, laser technology, optoelectronics and precise mechanics (including development, prototyping, CNC and laser micro-machining).

SQS Development and Production Services

- » Technical Development, Process Development

- » Mechanical Parts Design, Prototyping, Production

- » Hi-Tech Facilities for OEM or Contract Manufacturing

- » Custom Products Measurements and Testing

Our Mission

We will continue provisioning of development and production of a wide range of products from standard interconnect cables and passive fiber optic components to high-value added technically demanding passive and active optoelectronic solutions incl. products such as high-power laser beam delivery cables, folded and fused optical fiber bundles, high-power laser diode drivers, laser beam control units, precision SM and MM collimators for industrial applications, special fiber optic assemblies for photonic integrated circuits (PIC), hermetic feedthroughs for applications in high pressure or vacuum environments, 2D fiber arrays including variants with integrated optical microlenses, and other polarization maintaining (PM), high power, multi fiber, hermetic, armored opto-mechanical assemblies.

We will continue provisioning of development and production of a wide range of products from standard interconnect cables and passive fiber optic components to high-value added technically demanding passive and active optoelectronic solutions incl. products such as high-power laser beam delivery cables, folded and fused optical fiber bundles, high-power laser diode drivers, laser beam control units, precision SM and MM collimators for industrial applications, special fiber optic assemblies for photonic integrated circuits (PIC), hermetic feedthroughs for applications in high pressure or vacuum environments, 2D fiber arrays including variants with integrated optical microlenses, and other polarization maintaining (PM), high power, multi fiber, hermetic, armored opto-mechanical assemblies.

High quality and reliability ensured by a high level of technology, expertise, skills and experience are features we want our products and services to be perceived by our customers.

Maintaining the top technological level of the company, investing into manufacturing and R&D facilities, and uncompromising quality management will help us to become one of the leading companies focused on fiber optics and laser technology components development and manufacturing. We want to establish SQS as a strong competitive company capable of resisting external circumstances and competitive pressures. We will continue with the factory production program diversification mainly by fiber optic and laser technology products addressing also non-telecom industrial sectors. Our competitive advantage has been and will be our ability to supply complete tailor-made custom solutions including highly demanding industrial and military applications.

Certificates and Customer Audits

SQS has acquired not only widely recognized ISO certification including quality and environmental management systems according to ISO 9001:2008 and ISO 14001:2004 standards, but also very demanding certification proving that we have established and applied a quality management system for Assembling and Testing of Semiconductor Parts according to the ISO/TS 16949:2009 standard for automotive industry (note: currently the ISO/TS has not been recertified due to a planned end of contracted THT LED production). ISO certification and following regular auditing in SQS Vlaknova optika is performed by prestigious international certification organization TÜV SÜD.

SQS has acquired not only widely recognized ISO certification including quality and environmental management systems according to ISO 9001:2008 and ISO 14001:2004 standards, but also very demanding certification proving that we have established and applied a quality management system for Assembling and Testing of Semiconductor Parts according to the ISO/TS 16949:2009 standard for automotive industry (note: currently the ISO/TS has not been recertified due to a planned end of contracted THT LED production). ISO certification and following regular auditing in SQS Vlaknova optika is performed by prestigious international certification organization TÜV SÜD.

We have also been certified by our suppliers/business partners to prove our qualification to use their technologies including Diamond, Reichle & De-Massari, Gooch & Housego, and Avago Technologies.

Another very important proof of our high quality standards and uncompromised quality management are customer audits.

Customer References

Among our main customers, there are telecommunication operators, manufacturers of optical transmission systems, installation companies, cable TV network operators, and many other companies from various industrial sectors.

Among our main customers, there are telecommunication operators, manufacturers of optical transmission systems, installation companies, cable TV network operators, and many other companies from various industrial sectors.

Our customers include a wide spectrum of companies not only from telecommunications but also from many other industrial sectors where fiber optics and laser technology finds still more and more applications. These are primarily optical components developed for integration into larger units - modules and devices for various industrial applications using data transmission in the form of optical signals or laser beams, e.g. optical measuring devices and systems, sensors and sensor systems, diagnostic systems or production equipment in energy, engineering, chemical, petrochemical, mining, automotive, healthcare and other application areas.

Our Vision

- » Manufacturing of special fiber optic, laser technology and optoelectronic products for applications across all industry sectors

- » Gradually increase the share of developed and manufactured high-value added technically demanding solutions

- » Research and Development of new products, manufacture technologies, and production equipment

- » Product testing according to customer requests

- » Customer Support in the form of customer project management (e.g. technical support in the phase of project preparation)

- » Our company will continue R&D collaboration with technical universities and the Academy of Sciences of the Czech Republic.

Company's History

SQS Vláknova optika a.s. was founded in 1994, in Nova Paka, Czech Republic. The letters S-Q-S in the name of the company refers to the first letters of three founder members’ names: Jiri Simek, Wilhelm Quittner, Zdenek Svitorka; and the Czech expression “Vlaknova optika” means “Fiber Optics” in Engllish.

SQS Vláknova optika a.s. was founded in 1994, in Nova Paka, Czech Republic. The letters S-Q-S in the name of the company refers to the first letters of three founder members’ names: Jiri Simek, Wilhelm Quittner, Zdenek Svitorka; and the Czech expression “Vlaknova optika” means “Fiber Optics” in Engllish.

Initially the company was specialized in fiber optic patch cord and pigtail manufacturing exclusively based on connector technology of active core alignment.

In October 2000, SQS significantly broadened the assortment of manufactured products with a complete line of "classic" ceramic one-layer ferrule connectors, and started offering its fiber optic products and services to customers worldwide.

In December 2002, SQS Vláknová optika originally registered as a limited company was transformed to a corporation.

Other SQS Milestones:

- 2001 – Monitoring Link System (MLS) development

- 2002 – Development of technology for installation of connectors on PM fibers

- 2002 – PLC splitters development

- 2003 – Fusion Bi-conical Tempering (FBT) technology transfer

- 2006 – PLC splitters serial production

- 2008 – Special high-reliability product development for submarine applications

- 2009 – Serial contracted production of optoelectronic components

- 2010 – MEMS technology manufacturing process development, MEMS production line design and installation

- 2011 – Fiber optic sensors development

- 2012 – Introduction of the SQS LightView Campus project - the vision of SQS new factory with accomodation facilities based on long-term Sustainable Development Strategy of SQS Vláknová optika a.s.

- 2012 – Production of fiber optic components with antireflection coating

- 2012 – Serial production of new optoelectronic transmitters and receivers 150 Mbps

- 2013 – Intelligent Light Project

- 2014 – Fiber optic sensors

- 2014 – Production of Integrated LED Light Sources

- 2016 – Technology transfer of lensed LED production for automotive industry from Odelo. The serial production started in January 2017.

- 2017 – Low Profile Fiber Arrays (LPFA) based on newly developed Fiber Bending Technology

- 2017 – Fiber Coupled Microlens Arrays (FCMA) high-precision active alignment of optical fibers onto microlenses (Micro Lense Array – MLA) without a spacer between 2D array and MLA

- 2018 – Glued and fused fiber bundles

- 2019 – High power laser beam delivery cables

- 2020 – New types of vacuum and high-pressure optical fiber feedthroughs

- 2021 – Mini fiber optic assemblies for photonic integrated circuits (PIC)

- 2022 – High power laser diode driver, Project of SQS Laser Center

- 2023 – Automation of fiber optic production processes, serial production of microlensed fiber arrays assemblies for PIC