Precision CNC Machining

Production of high-precision mechanical components for optical, fiber optic, and other applications.

In the precision CNC machining department, we deal with the entire production and inspection process. Using the latest versions of CAM software, we carry out production feasibility studies, production technology optimization, production process simulation and CNC program preparation.

The workshop's modern machinery is selected to cover a wide range of requirements for the development of prototypes and the production of precision mechanical parts.

Machined materials include brass, copper, ARCAP, aluminum alloys, stainless steels, titanium, Kovar, Inconel, Invar and other difficult-to-machine materials.

High Precision Lathe

A lathe with special kinematics and rigidity for hard turning, equipped with a robust hydrostatic spindle that allows turning outer diameters with tolerances smaller than 1 µm.

A machine for manufacturing precise mechanical parts requiring internal turning operations with diameters starting from 120 µm. The machine offers high precision and stability for working with micron tools.

Further information

- Hydrostatic spindle with a maximum of 12,000 RPM

- Unique High-precision collet clamping system

- Ultra-rigid design of linear guides

- Thermal stability of all key components

- Posibility to expand standard tool positions with a powered tool

High Precision Milling

Three-axis milling center with additional rotary table for five-axis machining. Unique positioning and rigidity together with high-speed spindle make the machine suitable for finishing operations including optical surface production and production of parts with high precision requirements.

Further information

- X / Y / Z axis travel: 300 / 300 / 300 mm

- Ultra-precise aerostatic spindle with a maximum speed of 80000 rpm

- Precise measurement in the XY plane with a resolution of 0.01 µm and a positioning accuracy of ± 0.5 µm

- Simultaneous five-axis machining with rotary table

- Laser measurement of tools with damage detection

- Automatic tool changer magazine, 30 positions

Turning-Milling Center

The machine based on the main spindle, counter spindle and tool spindle brings balanced turning and milling capabilities, a large workspace and machine variability tailored to complex prototype production.

Further information

- Spindle bore 65 mm, standard turned diameters up to 300 mm, maximum turning diameter 640 mm, maximum possible turning length 1100 mm

- X / Y / Z axis travel: 700 / 250 / 1100 mm

- Linear measurement with a resolution increment of 0.05 µm in the X and Y axes

- Tool spindle with adjustable working angle within 225°, maximum speed of 12,000 rpm and simultaneous five-axis machining capability

- Various workpiece clamping options for turning and milling

- Automatic tool changer magazine, 40 positions

Swiss-Type Long-Turn Lathe

Main spindle and counter spindle for complex machining. Possibility of turning, drilling, milling and threading on a pitch circle.

Further information

- Machining diameter range 0.5 mm to 23 mm, production of long, slender parts

- 12 controllable axes, 27 tool positions with the possibility of clamping up to 41 tools

- Driven tool unit with adjustable working angle (B axis) and simultaneous five-axis machining capability

- Tool positions for deep hole drilling

Gantry Coordinate Measurement

A high-precision gantry coordinate measuring machine (CMM) that enables high-precision tactile measurement of large and small components. Workstations, including an off-line station, are used for programming, simulating, and optimizing measurement programs.

Further information

- Measurement space size X/Y/Z: 700/1000/500 mm

- Scanning or capturing individual points in an automatic measurement process

- Air bearing travel, rigid machine structure

- Located in a separate temperature-controlled room for the best measurement results

- Possibility of temperature compensation of the measured component

- Accuracy in 3D process: 0.5 µm + L/500 µm

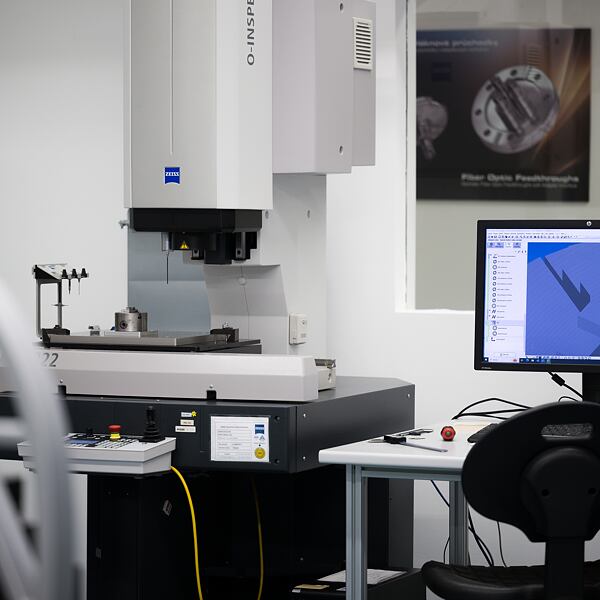

Multisensor Coordinate Measurement

Multi-sensor coordinate measuring machine with the possibility of measuring using a camera and touch measurement, including their combination. Workstations, including an off-line station, are used for programming, simulating and optimizing measuring programs.

Further information

- Measurement space size X/Y/Z: 300/200/200 mm

- Scanning or capturing individual points

- HD camera with image processing

- Circular and coaxial light for optimal adjustment

- Accuracy in 3D process: 2.4 µm + L/150 µm

3D Optical Measuring Machine with Rotary Axis

Used for inspection of the profile and structure of the surface using non-contact measurement. The machine is equipped with its own lenses and software for data processing, including the possibility of automatic measurement. Another feature is a motorized rotary axis.

Further information

- Optical measurement of dimensions, profile and roughness

- Focus variation principle

- Lenses with magnification 5x, 10x, 20x, 50x, 100x

- Motorized rotary axis for obtaining complete 3D data

- For 100x lens:

- Vertical resolution 10nm

- Minimum measurable roughness Ra 0.03 µm, Sa 0.015 µm

- Minimum measurable radius 1 µm

Contact Roughness and Profile Measurement

The machine provides the possibility of surface analysis by contact method using small measuring probes. Used for measuring surface roughness, checking small details on all components, especially on components made of e.g. glass or ceramics.

Further information

- Own measuring and evaluation stations

- Interchangeable measuring probes

- Possibility of inspecting shiny materials that are more difficult to inspect with optical instruments

Contact

If you have any questions or requests, please do not hesitate to contact our specialist.

Sales department

Phone: +420 493 765 111

sales@sqs-fiber.cz