News

The presentation of secondary schools and employers should show the continuity of schools to individual employers in the Jičín region and at the same time it should be an inspiration for future students when choosing a secondary school. The organizers of the event are the Hradec Králové Region and the Regional Chamber of Commerce of the Hradec Králové Region.

The presentation of secondary schools and employers should show the continuity of schools to individual employers in the Jičín region and at the same time it should be an inspiration for future students when choosing a secondary school. The organizers of the event are the Hradec Králové Region and the Regional Chamber of Commerce of the Hradec Králové Region.

The accompanying event is a fair of current job opportunities.

Presentation of secondary schools and employers takes place from 20 to 21 February 2017 at the Masaryk Theater in Jičín.

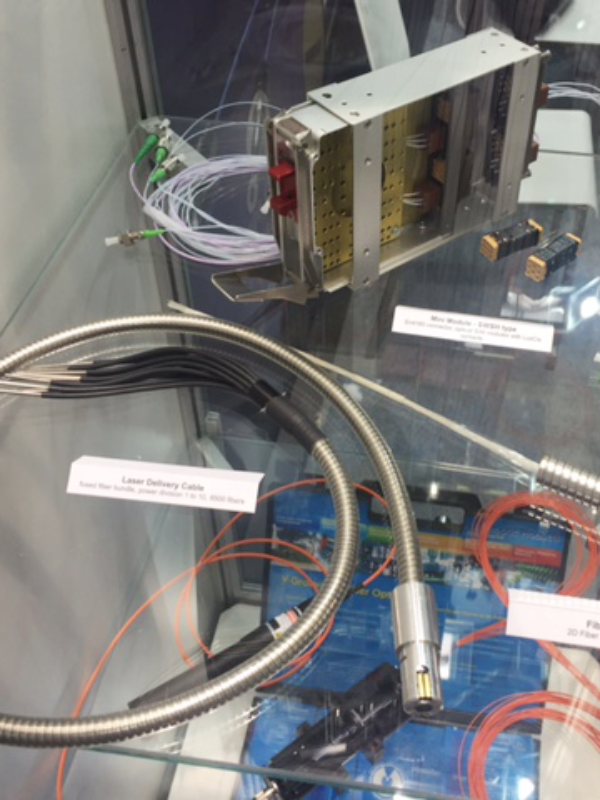

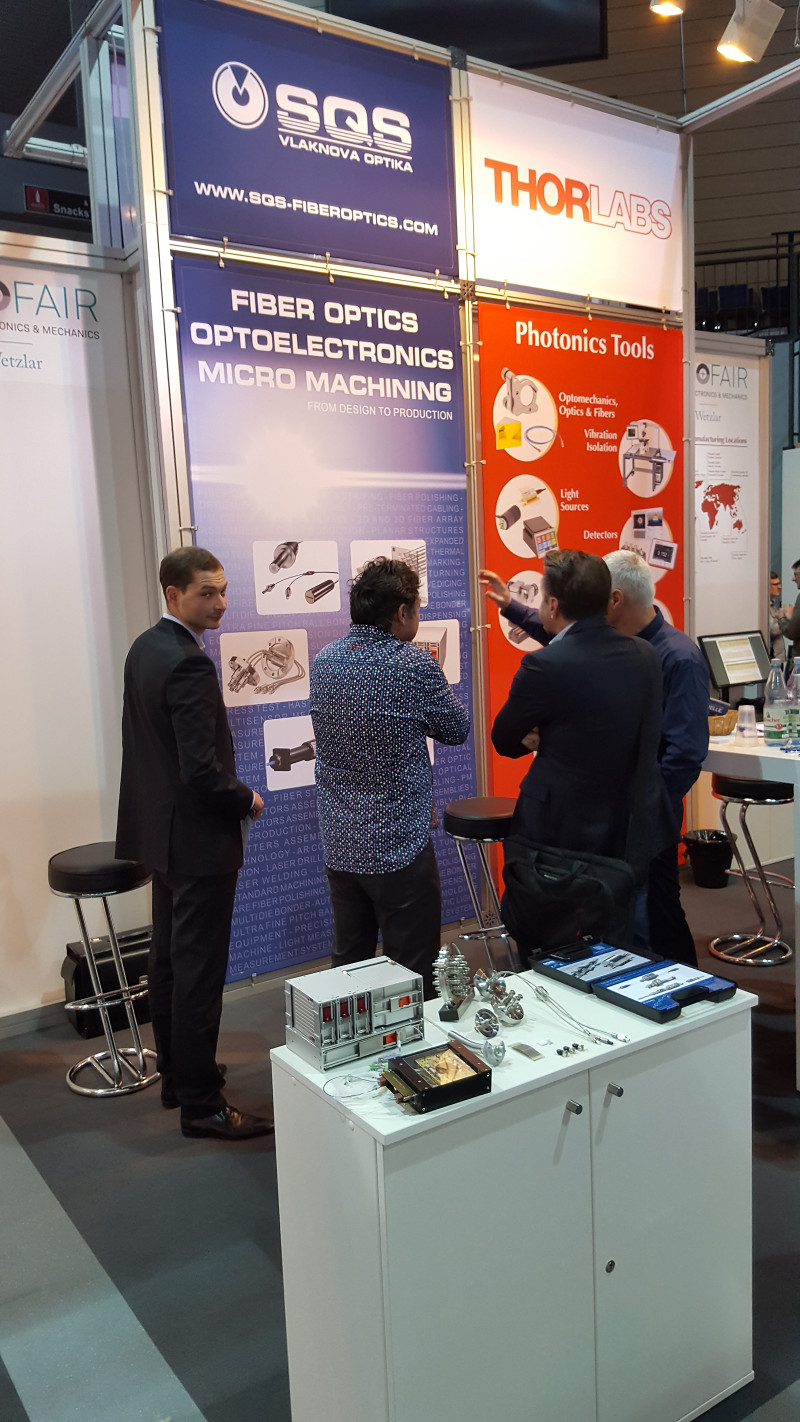

Do not hesitate to come and see us on the stand. We are glad to welcome you here and introduce you to SQS's core activities in the field of fiber optic and optoelectronics manufacturing and development, to familiarize you with what work you can do in the future and, of course, we will also inform you about the current job offer, which we are looking for suitable candidates.

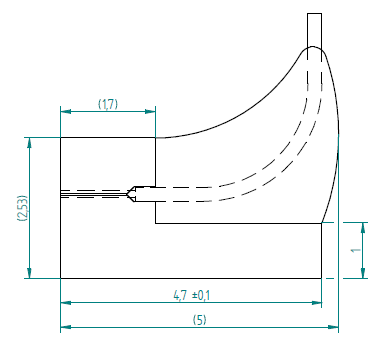

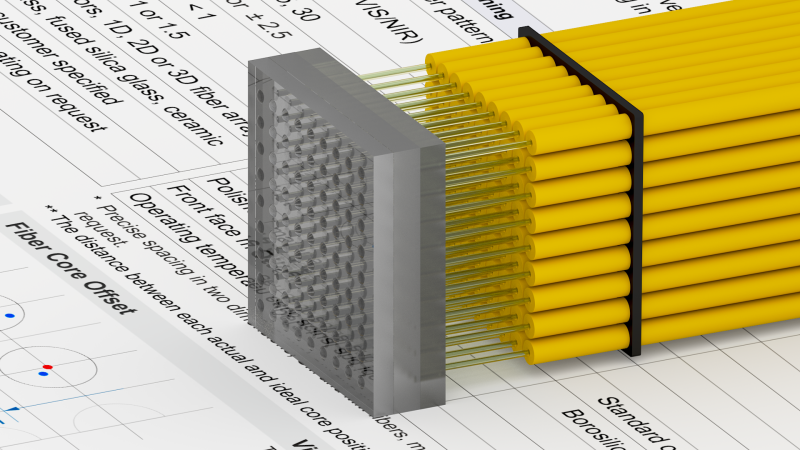

SQS has developed and offers potential customers a very interesting fiber array with optical fibers outputting at an angle of 90 ° with a very small bending radius. The main advantage of this solution of fiber array with bended optical fibers is an achievement of a very low profile of the component. Low Profile Fiber Arrays (LPFA) may be used e.g. for mounting on a printed circuit board where it can be directly aligned to an optical transceiver or other optical components in the form of a semiconductor chip.

SQS has developed and offers potential customers a very interesting fiber array with optical fibers outputting at an angle of 90 ° with a very small bending radius. The main advantage of this solution of fiber array with bended optical fibers is an achievement of a very low profile of the component. Low Profile Fiber Arrays (LPFA) may be used e.g. for mounting on a printed circuit board where it can be directly aligned to an optical transceiver or other optical components in the form of a semiconductor chip.

The SQS solution of LPFA (Low Profile Fiber Array) is based on the newly developed Bended Fiber Technology for bending fiber-array-output fibers up to 90° while maintaining minimal dimensions.

Because of the initial request of low profile fiber array, the solution was very demanding. The great success of SQS is that, despite the extremely adverse conditions for the transmission of the optical signal, the Low Profile Fiber Array with optical fibers outputting at an angle of 90 ° achieves very good transmission parameters.

Features:

- Min. dimensions: hight 4-5 mm, width 2.5 mm, length 2,5 mm (depends on number of channels

- Guaranteed attenuation IL

- Fibers terminated with any type of optical connector

- Optical fiber G.657.B3

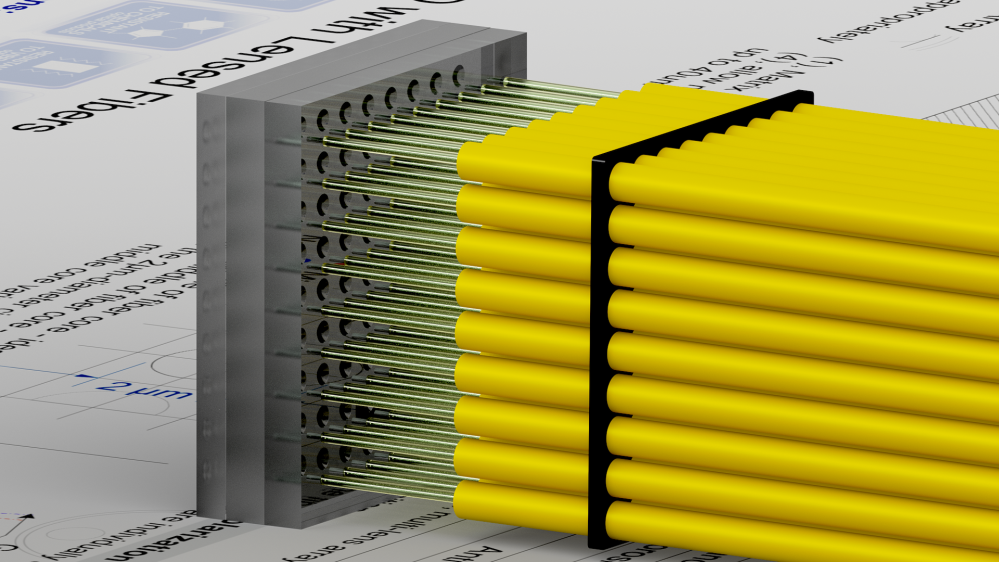

SQS has developed and offers 2D fiber arrays actively aligned onto microlens arrays (MLA). Thanks to the unique manufacturing process of Fiber Coupled Microlens Arrays including high-precision active alignment of optical fibers onto microlenses without any spacer between 2D array and MLA, SQS may offer customized solutions with high number of functional channels and minimal angle deviation of beams outputting the lenses. SQS Fiber Coupled Microlens Arrays keeps beam pointing accuracy less than 0.2° from ideal beam axis.

SQS has developed and offers 2D fiber arrays actively aligned onto microlens arrays (MLA). Thanks to the unique manufacturing process of Fiber Coupled Microlens Arrays including high-precision active alignment of optical fibers onto microlenses without any spacer between 2D array and MLA, SQS may offer customized solutions with high number of functional channels and minimal angle deviation of beams outputting the lenses. SQS Fiber Coupled Microlens Arrays keeps beam pointing accuracy less than 0.2° from ideal beam axis.

Due to the precise active fiber alignment onto the matrix of aspheric lenses, SQS may guarantee for all channels minimum insertion losses, and minimum tilts and offsets of outgoing light beams.

Upon request, SQS may provide also additional antireflection broadband coating that ensures minimum losses due to back reflections, or high-power type of solution.

SQS se zúčastní veletrhu pracovních příležitostí, který se koná 7. září 2017 v jičínském Masarykově divadle. Hledáte-li zaměstnání, přijďte se podívat na náš stánek, kde vám představíme naši firmu a nabídneme zajímavé pracovní příležitosti.

SQS se zúčastní veletrhu pracovních příležitostí, který se koná 7. září 2017 v jičínském Masarykově divadle. Hledáte-li zaměstnání, přijďte se podívat na náš stánek, kde vám představíme naši firmu a nabídneme zajímavé pracovní příležitosti.

Nabízíme

- klidné, čisté a moderní pracovní prostředí

- možnost pracovat pouze v 1směnném provozu

- možnost zkráceného úvazku

Nabízíme také mnoho výhod a odměn:

100 Kč stravenky, 1 000 Kč měsíčně při 100% docházce, náborový příspěvek až 15 000 Kč, kurzy anglického a německého jazyka, zaměstnanecké telefonní tarify včetně výhodných tarifů pro rodinné příslušníky, odměny za doporučení nového zaměstnance až 11 000 Kč, příspěvek na penzijní připojištění, příspěvek na pojištění odpovědnosti, možnost ubytování (pro vybrané pracovní pozice) a další.

SQS has extended its wide range of vacuum optical fiber feedthroughs by optoelectronic feedthroughs. Optoelectronic feedthroughs include also electrical connector interface (e.g. D-Sub, Micro-D, USB, and various round multi-pin connector plugs).

SQS has extended its wide range of vacuum optical fiber feedthroughs by optoelectronic feedthroughs. Optoelectronic feedthroughs include also electrical connector interface (e.g. D-Sub, Micro-D, USB, and various round multi-pin connector plugs).

Optical and electrical feedthroughs may be implemented in variety of flanges according to custom requirements.

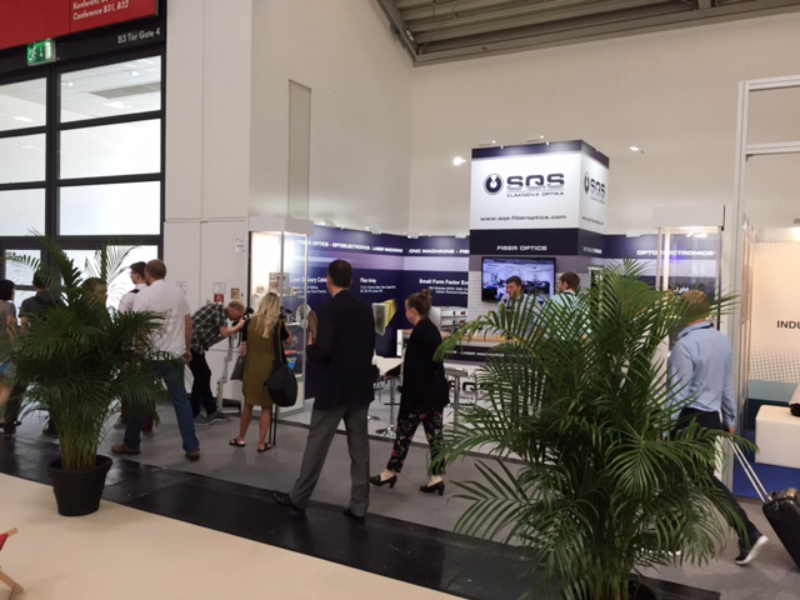

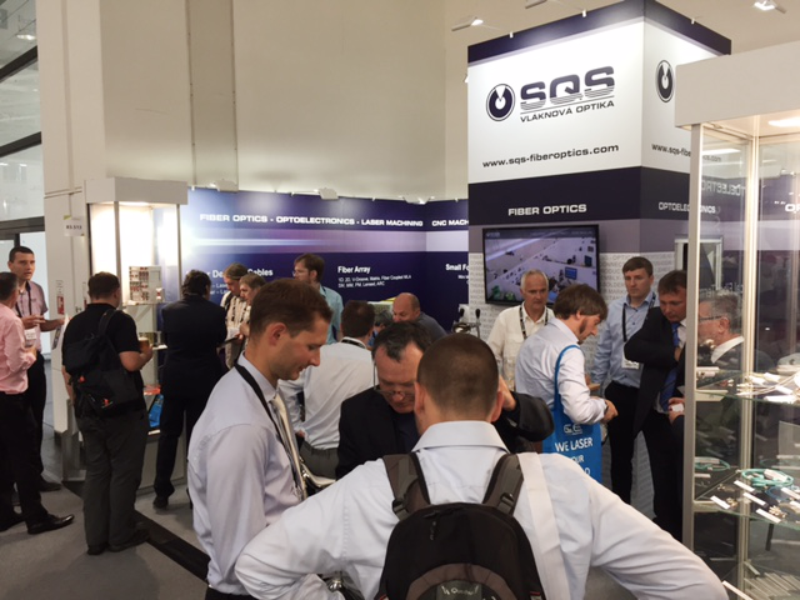

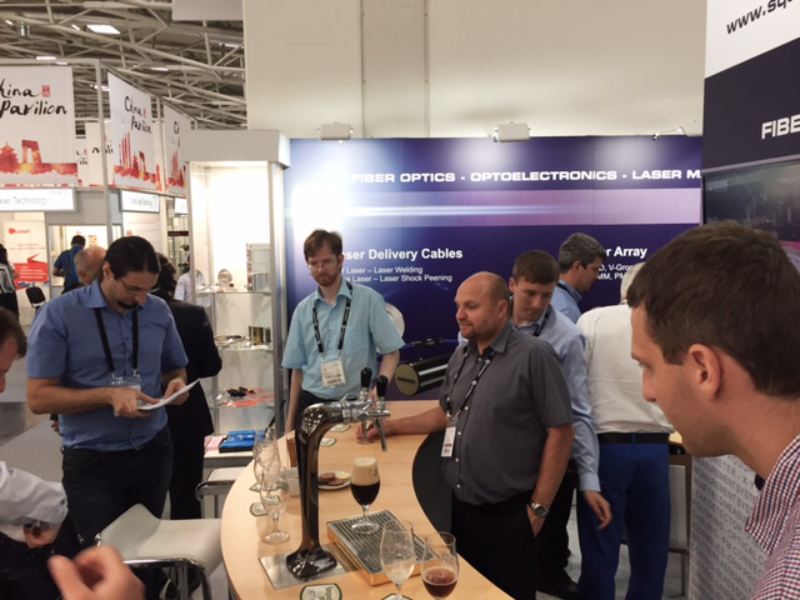

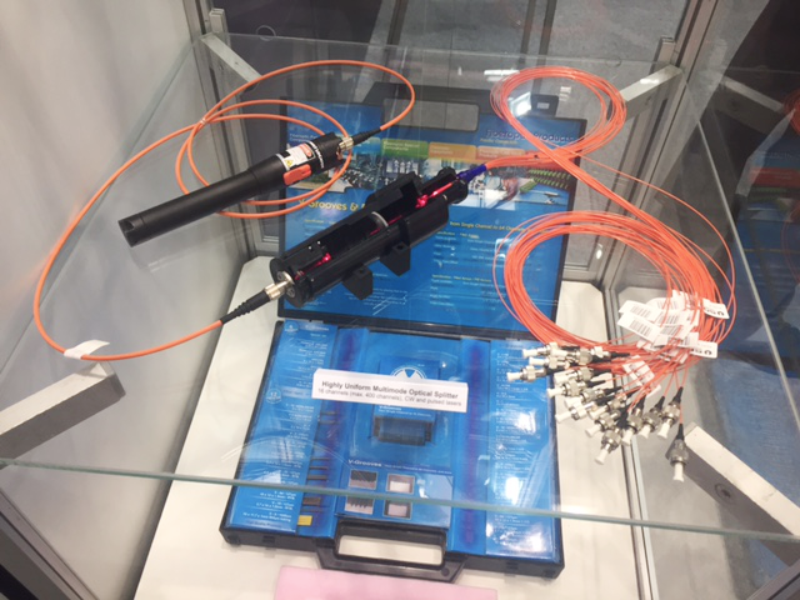

SQS will present its current portfolio of products and services from areas of fiber optics, optoelectronics and micro machining at the booth number B3.513.

SQS will present its current portfolio of products and services from areas of fiber optics, optoelectronics and micro machining at the booth number B3.513.

Come and see us, you will be welcome!

Laser World of PHOTONICS is the International Trade Fair for Photonics Components, Systems and Applications, that has been held in Munich since 1973. It combines technology with industrial application sectors for the widest variety of industries and uses.

Every two years key players of the photonics industry come to Munich to meet at the industry’s most important marketplace. The fair gives participants from more than 70 countries a complete overview of all topics that pertain to photonics on 55,000 square meters of exhibition space.

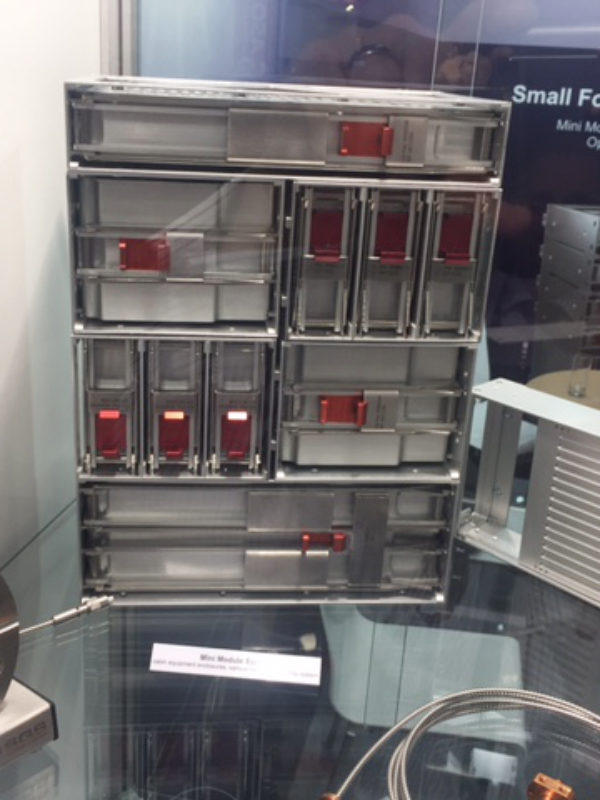

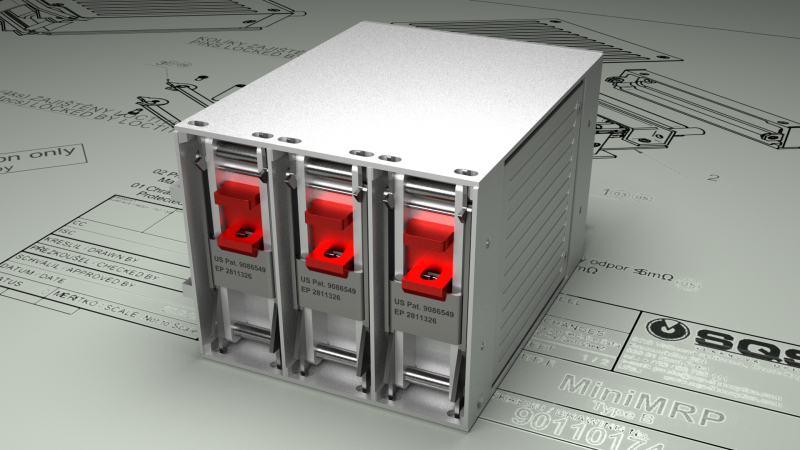

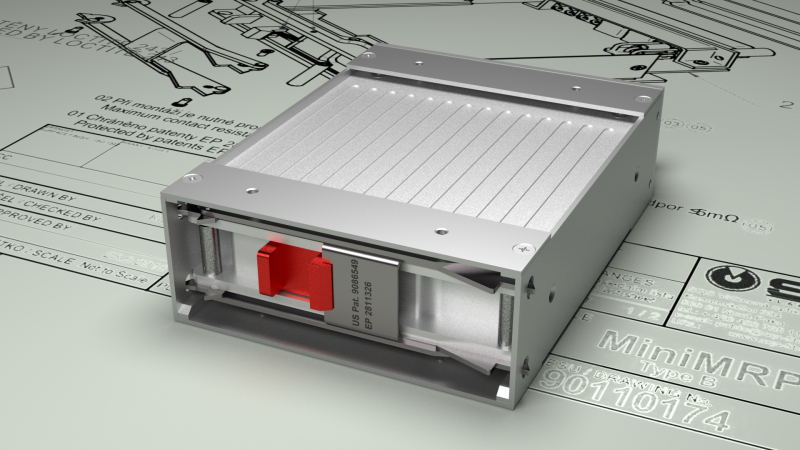

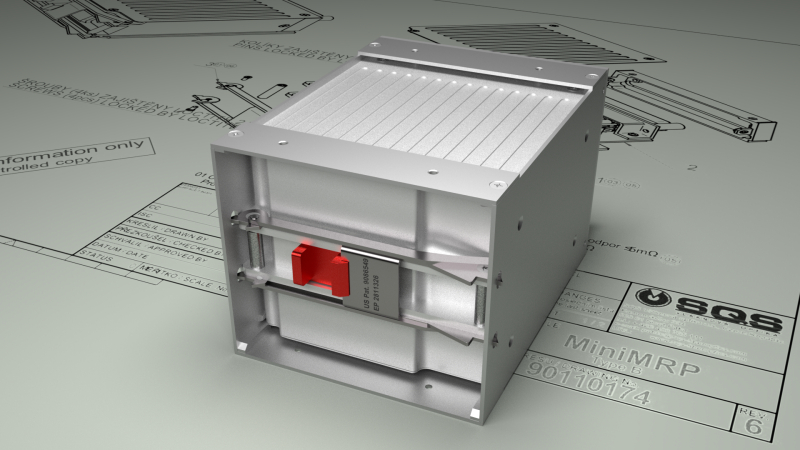

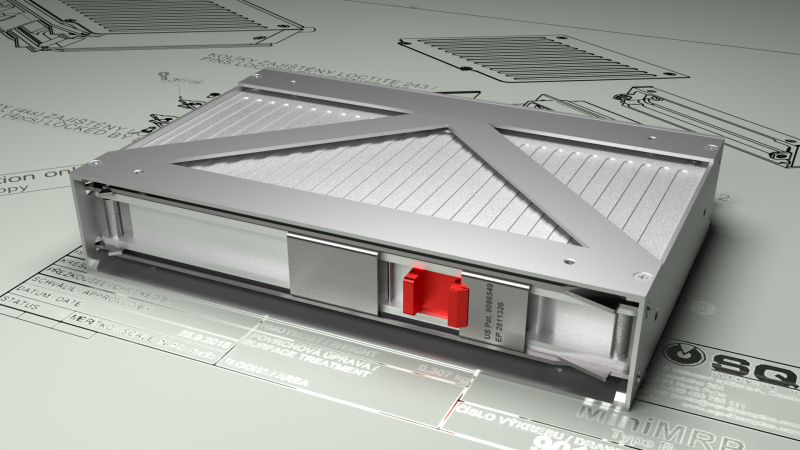

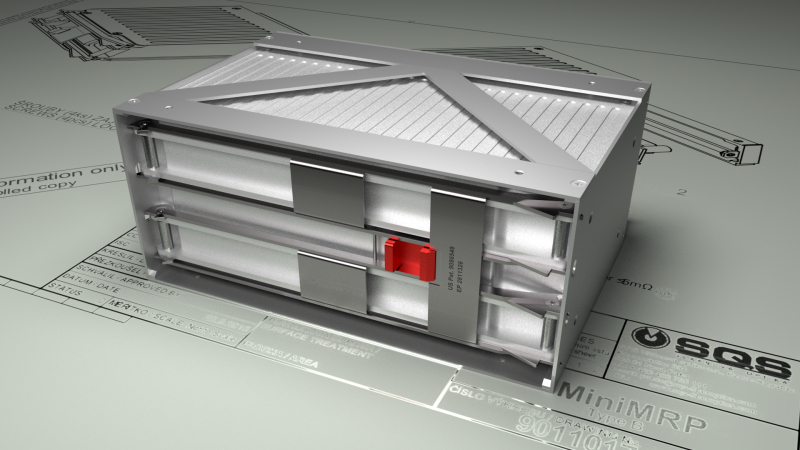

SQS is involved in creation of an ARINC 836A standard for small cabin enclosures Type II – Miniature MRP (Modular Rack Principle) called Mini Modules (MM).

The new standard creates a concept for the installation of optical and electrical devices in the cabin of the aircraft, with an emphasis on smaller dimensions, less weight, resistance of module and frame connectors to operating errors, modularity and interchangeability of individual modules.

Mini modules can be used in all industrial applications where electronic or optical components of the system will be operated under demanding conditions, especially with respect to vibrations and a wide range of operating temperatures. For example in modern aircrafts with composite fuselage, the MM distributed system can deploy Mini Modules with electronics to multiple locations in the fuselage to provide a very efficient drain of the large amount of heat that the electronics generate.

SQS offers Mini Modules in all ARINC 836A variants equipped with its own design of locking mechanism ensuring a defined insertion and locking of the Mini Module. The design of the locking mechanism by SQS is not part of the ARINC 836A standard and it is protected by the European and American patent registered under number EP 2811326 resp. US 9086549. SQS offers Customers who would like to produce Mini Modules individually to use a license for the patented locking mechanism. Detailed license conditions will be sent to specific customers on request.

We would be pleased to welcome you at our stand no. D4b. The presentation of SQS is focused on new products based on company’s unique R&D and manufacturing capabilities resulting in combination of know-how and skills in three very demanding technical disciplines: fiber optics, optoelectronics, and micro machining. SQS is going to introduce especially new versions of optical fiber feedthroughs, fibre bundles, high-power and PM components, and also new activities in optoelectronic production and micro machining.

We would be pleased to welcome you at our stand no. D4b. The presentation of SQS is focused on new products based on company’s unique R&D and manufacturing capabilities resulting in combination of know-how and skills in three very demanding technical disciplines: fiber optics, optoelectronics, and micro machining. SQS is going to introduce especially new versions of optical fiber feedthroughs, fibre bundles, high-power and PM components, and also new activities in optoelectronic production and micro machining.

The W3 FAIR is an interdisciplinary networking trade fair for the fields of optics, electronics and mechanics. It provides these high-tech sectors with a new, multidisciplinary forum for information, innovation and contact in the traditional location of Wetzlar in Germany.

The W3 FAIR promotes communication and networking among experts and paves the way for innovative solutions and new business - a real model for success.

We have expanded our portfolio of vacuum feedthroughs. Now we are offering such an adaptor featuring feedthroughs, which are able to seal polarization maintaining fiber (PMf) within themselves with minimum insertion loss and maximum extinction ratio.

We have expanded our portfolio of vacuum feedthroughs. Now we are offering such an adaptor featuring feedthroughs, which are able to seal polarization maintaining fiber (PMf) within themselves with minimum insertion loss and maximum extinction ratio.

These feedthroughs are set in a wall of a flange, providing interfacing between normal and high vacuum environment.

Automation of production of optical fiber components and serial production of high-precision fiber arrays with collimators

OP PIC - INNOVATION - IX. CALL

The aim of the project is to automate production processes in the production of fiber optic components and to start automatic serial production of new fiber optic modules with high-precision fiber optic arrays with collimators. The design of these components has been developed and optimized for multi-channel optical signal transmission between optical fibers and the corresponding inputs and outputs of photonic integrated circuits (PICs) for a new generation of photonic devices and systems with high transmission capacity.

Expansion of development capacities with CNC machining and measurement technologies with submicron precision

OP PIK - POTENTIAL - VII. CALL

The aim of the project, which is currently in the implementation phase, is to expand the research and innovation capacity with CNC machining and measurement technology for the development of extremely precise mechanical parts of special optical assemblies with high added value. The project builds on many years of experience in the development of precision mechanical parts and fundamentally shifts the company's development capabilities in the field of machining and contact measurement to submicron precision. The motivation for such precision is research applications focused on unique combinations of precision mechanics and top optics.

Offer of Supported Infrastructure Development Services

The new equipment of the development workshop of the Precision CNC Machining and Measurement Department advances the company's machining and metrology development capabilities to the currently highest achievable technological maturity in the field of submicron precision and thus opens up space for the implementation of research and development projects in new application areas of fiber optics.

Purchased machines:

- CNC lathe for hard machining

- Coordinate measuring machine

- Advanced dimensional control of workpieces

List of exams:

- Development of a functional sample, prototype, rotary mechanical part with a requirement for micron (1 µm = 0.001 mm) to submicron (<1 µm) accuracy of outer and inner diameters with the required mutual alignment of the outer and inner diameter in the order of microns.

- Micro-drilling of holes with diameters according to the optical fiber used (e.g. typically from a diameter of 0.080 mm to a diameter of 1.050 mm).

- Related high-precision measurement of the mechanical part under development on a coordinate measuring machine

- Dimensional control of workpieces

The price charged for the operation or use of this infrastructure will correspond to the market price. The price of the contract for the provision of infrastructure will be determined based on the specific demand of the entity that will be interested in the offered services.

SQS Educational Center - DS Saurus

OP EMPLOYMENT - SUPPORT FOR THE ESTABLISHMENT AND OPERATION OF CHILDREN'S GROUPS FOR ENTERPRISES AND THE PUBLIC

The aim of the project is to build and operate a childcare facility. A corporate children's group facility with a capacity of 12 children was established. It is currently in the operation phase.

Purchase of machines and equipment for prototyping

OP PIK - POTENTIAL - I. CALL

On December 9, 2016 SQS Fiber Optics received a grant decision. The innovation project of "Purchase of machinery and equipment for prototyping" received support from the Operational Program Enterprise and Innovation for Competitiveness, support program Potential 1st call.

The main objective of the project is the implementation of laser and CNC micromachining for development of high precision mechanical parts of fiber optic and optoelectronic products.

The project includes the acquisition, installation and commissioning of machinery and equipment for the production of prototype products developed by the research and development department of the company. The aim is to enable the development department to manufacture prototypes of precision mechanical parts of various fiber optic and optoelectronic products, incl. solutions for demanding industrial applications and specific customized solutions. The aim of the project is to increase the competitiveness of the company. The project will in particular contribute to streamline and speed up development works and thus accelerate the implementation of the results of industrial research and development into production.

As of the end of the project, i.e. from 30/06/2018, all acquired technology is also available as a service to other entities for carrying out the following tests. The supported infrastructure services may be used by third parties exclusively for conducting research, e.g. for the construction of functional samples and prototypes.

The price charged for the operation or use of this infrastructure will correspond to the market price. The price of the contract for the provision of infrastructure services will be determined based on the specific demand of the entity that will be interested in the offered services. Services offered by the supported infrastructure:

IR Femtosecond laser (incl. high-precision workpiece positioning)

- tests of machinability of glasses with a femtosecond laser

- tests of direct writing of waveguides into glasses

- LIDT (Laser Induced Damage Threshold) test for an IR femtosecond laser

Multifunctional CNC machining center

- high-precision machinability tests of mechanical parts (including materials that are difficult to machine, e.g. titanium, duplex steel or materials from the category of superalloys, e.g. inconel)

- machinability tests of rotary components, which, in addition to turning operations, often contain a large proportion of milling and drilling operations at various angles, including free-form surfaces

- finding a functional and manufacturing optimal design solution

High precision CNC milling center

- machinability tests in micron to sub-micron accuracies (both for traditional metal materials, e.g. stainless steel, and for hard-to-machine materials such as glass and ceramics)

- machinability tests of complicated shaped parts

Coordinate measuring machine for optical measurement of roughness and profile

Optical measurements of workpieces

- precision mechanical parts measurements

- quality of surfaces measurements

Optical measurements of machining tools

- geometry and quality of cutting edges of machining tools measurements

- detection of defects on machining tools

Note: Especially in the tasks of achieving polished surfaces and machining with micron accuracies, it is necessary to pay maximum attention not only to the machine tool and the technology used, but also to the machining tools. In the case of high precision machining, it is necessary to perform an inspection of the machining tools before they are used in the machining process.