News

On September 24th the regional round of the Talent for Companies 2019 competition took place. The competing teams consisted of three elementary school pupils, three high school students, a teacher and an expert from practice leading the team as a captain.

This year's 4th edition of this competition took place at the Secondary School of Mechanical and Electrical Engineering in Nová Paka. Three teams of eight, consisting of pupils of the fifth grade of the Elementary School in Komenského Street, students of the second year of the host High School of Mechanical and Electrical Engineering and representatives of three important employers - Seco Industries, s.r.o., Continental Automotive Czech Republic s.r.o. and SQS Vlaknova optika a.s. The competition task was to build a model of polytechnic kit prepared exclusively for this competition.

The winner was the team of SQS Vláknová optika a.s. led by Milos Dolejsi and the team advanced to the regional final round, which will take place on November 15 in Hradec Kralove.

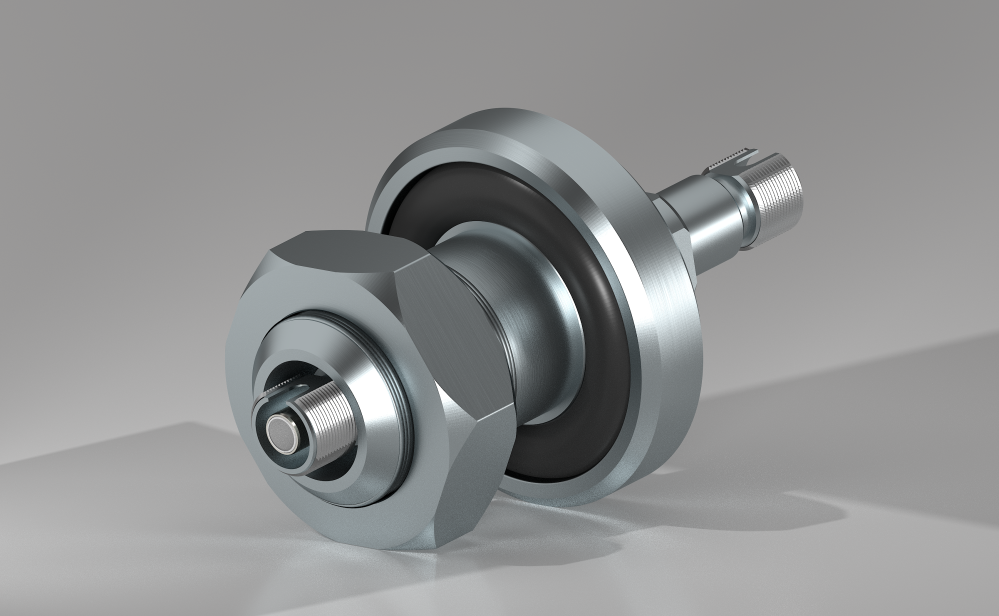

SQS offers many types of vacuum fiber optic feedthroughs as well as high pressure fiber optic feedthroughs. M16 vacuum fiber optic adapter feedthrough construction has been optimized for high vacuum applications. This is a solution suitable for a wall thickness of 7 mm to 13 mm with a hole diameter of 16.5 mm to 17 mm.

Application examples can be seen in various industries, also in military applications, oil and gas applications, etc. Fiber optic feedthrough flange is fully demountable, i.e. single feedthroughs can be easily replaced. SQS has developed its own technology for the optical fiber sealing.

This technology allows working with different types of optical fibers including polarization maintaining fibers (PM ).

Words of Appreciation by Chairman of the Board

I personally hired Jindriska Svecova in June 2000. She joined the sales department as an export manager.

After a short time Jindriska profiled herself as a very creative-minded employee and became an indispensable part of the sales team. Since 2002 she has worked as a Development and Strategy Officer. Jindriska actively participated in important decisions on the direction of further development of SQS Vlaknova optika.

She was involved in establishing and maintaining a very successful project with the Canadian company JDS Uniphase. This cooperation with the world leader in components for major telecommunications equipment manufacturers has significantly shifted our company. We have become a major supplier of optical components for the infrastructure of optical transmission systems.

In 2003 we established cooperation with the English company Sifam (now Gooch & Housego). We concluded a contract for production of optical components for aerospace and telecommunications. Since 2004 we have started to produce and supply optical components for undersea transmission systems for this company. Jindriska contributed greatly to the success of this long-term cooperation. Since the very beginning to present days she has participated in creation of contracts and setting conditions for cooperation as well as in everyday communication and maintenance of above-standard relations with Gooch & Housego.

Jindriska has always worked conscientiously, responsibly, proactively, with high expertise and a great deal of commitment.

I would like to thank Jindriska for more than 19 years of creative activity and great work for SQS. The results of her work have contributed to the good reputation of our company.

We wish Jindriska Svecova good health, permanent well-being and satisfaction in private and next professional life.

With respect

Wilhelm Quittner, Chairman of the Board of SQS Vlaknova optika a.s.

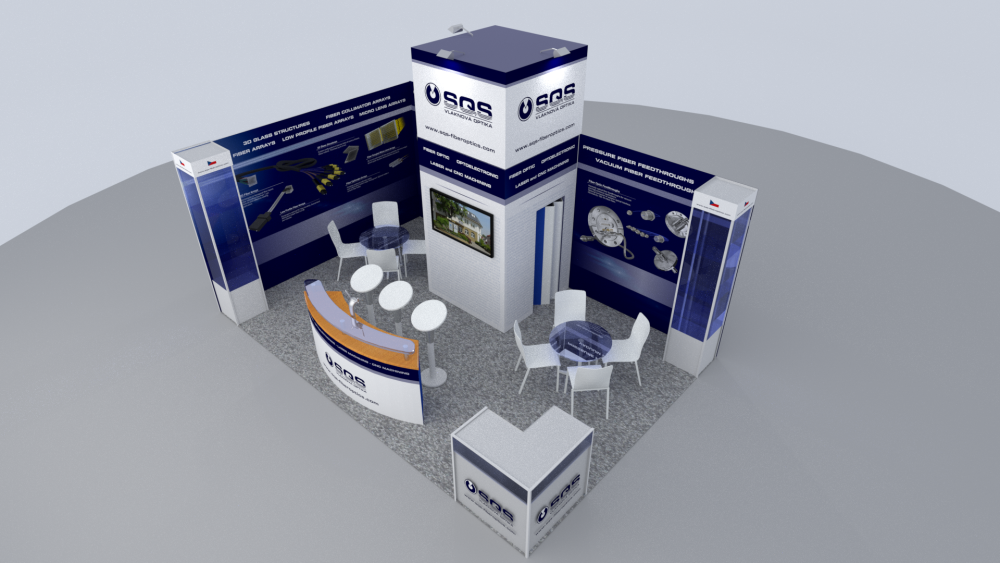

On June 24-27, 2019 SQS will be exhibiting at the Laser World of Photonics trade show in Munich. Laser is the world's leading trade fair and congress focusing on photonic components, systems and applications. The fair brings together research and the photonic industry to promote the use and further development of photonic solutions.

On June 24-27, 2019 SQS will be exhibiting at the Laser World of Photonics trade show in Munich. Laser is the world's leading trade fair and congress focusing on photonic components, systems and applications. The fair brings together research and the photonic industry to promote the use and further development of photonic solutions.

SQS will present its current portfolio of fiber optic, optoelectronic and micromachining products and services. The presentation will focus mainly on new fiber optic components developed by SQS. One of the most interesting ones is the high-power laser interconnection cable for high-energy laser beams, which are produced by special technology by bundling up to several thousand optical fibers. Other interesting products are, for example, various types of fiber fields including a very low profile solution that was developed to connect optical fibers directly to semiconductor optical components on printed circuit boards, or fiber optic feedthroughs that allow optical fiber installation and transmission of optical signals between environments with a high pressure difference, e.g. from sensors placed in vacuum or vice versa in high pressure environments.

Come to us at stand number 235 in hall B3, you will be welcome!

In 2019 SQS Vláknová optika celebrates its 25th anniversary.

In 2019 SQS Vláknová optika celebrates its 25th anniversary.

For a quarter century of existence, the company has built a very good name in our country and abroad in the field of development and production of fiber optics and optoelectronics components for various devices and systems working with optical signals and data.

From the first few employees working in one room, their number has gradually grown to just nearly 300, and the SQS premises in the heart of Nova Paka today comprise several buildings with clean room manufacturing facilities and modern technologies.

Since the initial production of fiber optic interconnect cables with one type of connector technology (Diamond active core-alignment technology) and an exclusive focus on telecommunications, the assortment has expanded considerably. The current range of components produced in SQS comes largely from its own development and is also applied in many other fields. Company’s main fiber optic products include optical interconnect cables with optical connectors, optical signal splitters for splitting the power of an input signal into multiple output fibers, laser delivery cables for high-energy laser beams transfer, optical fiber arrays, fiber feedthroughs and other products, e.g. for applications in optical telecommunication networks, data centers, measurement and sensor technology and other applications across industries including aerospace, defense, medicine, engineering or underwater communications.

In the field of optoelectronics, the main products of SQS are special LEDs with integrated optical lenses for various types of automobile lighting and lighting modules containing multiple LED chips, optics, optionally also intelligent lighting parameters control.

The resulting solutions of SQS products are often a combination of optics, fiber optics and optoelectronics, but also precision mechanics as the design and precise manufacturing of mechanical components are of no less importance to the overall solution. That's why the company has recently invested heavily in precision laser and CNC machining.

SQS sees its future in further development of company's existing strengths and its ability to offer customers comprehensive services from technical development and design through prototype development to production processes development and serial production.

SQS is aware of the fact that the company's main capital is overall the people working in the company. Their knowledge and skills combined with state-of-the-art technologies are the key to finding solutions and the following production. Since SQS is built on innovations and the development of new components, often tailored to customer requirements, the company must have a strong development department currently counting about 60 engineers including four with PhD degrees. SQS employee support for further education and their independent scientific work is a matter of course in this respect.

The company wants to further develop cooperation with secondary and higher education institutions, continue to cooperate with experts from Czech and foreign research organizations, but also to give opportunity to all who have addressed the company's focus, make them sense and are interested in innovative solutions and production built on modern technologies.

Let’s wish SQS to further implement its plans, overcome obstacles, and successfully continue the journey that began 25 years ago.

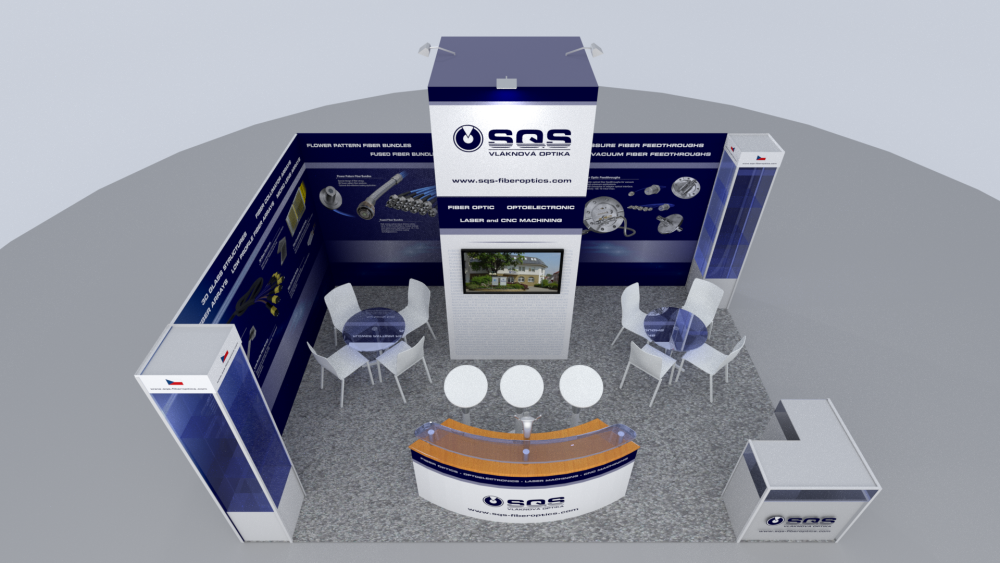

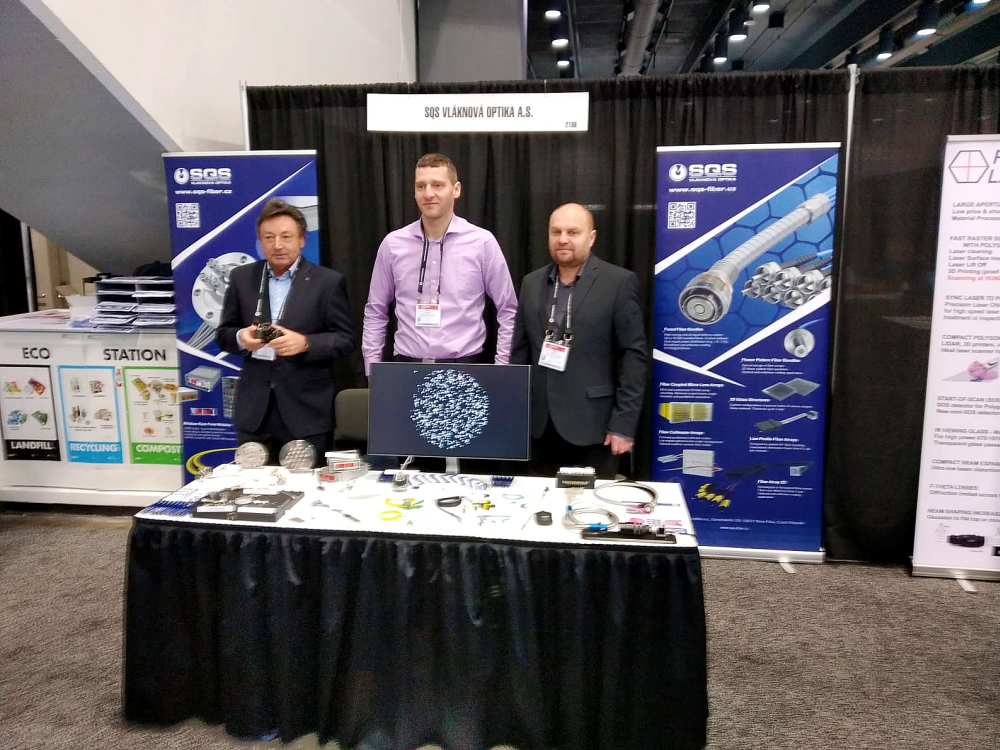

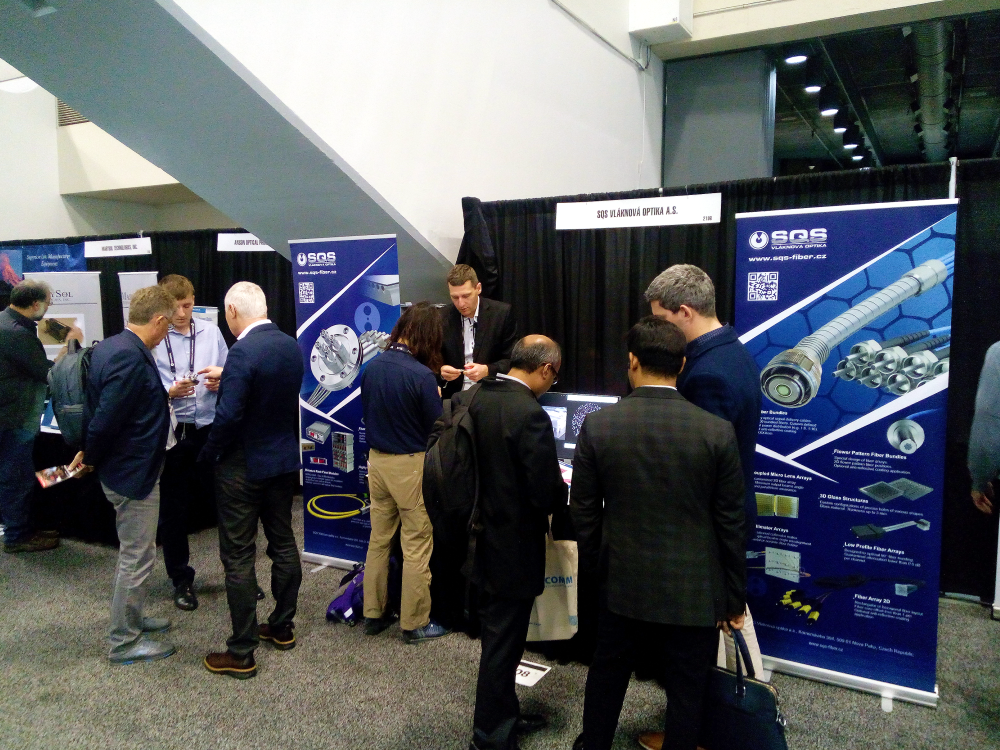

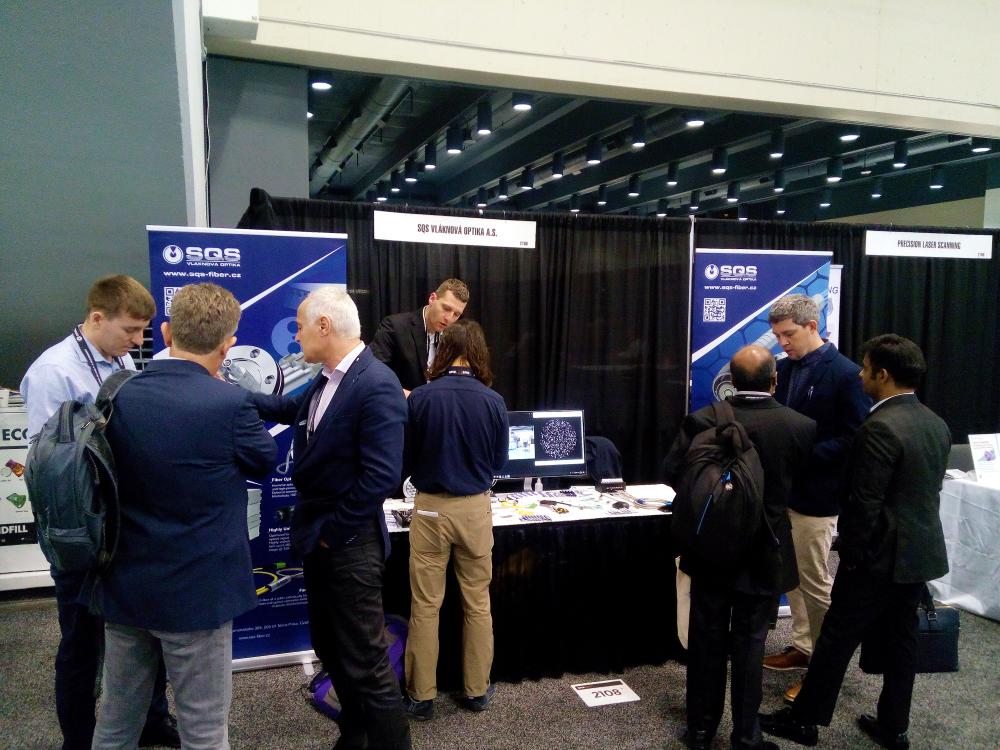

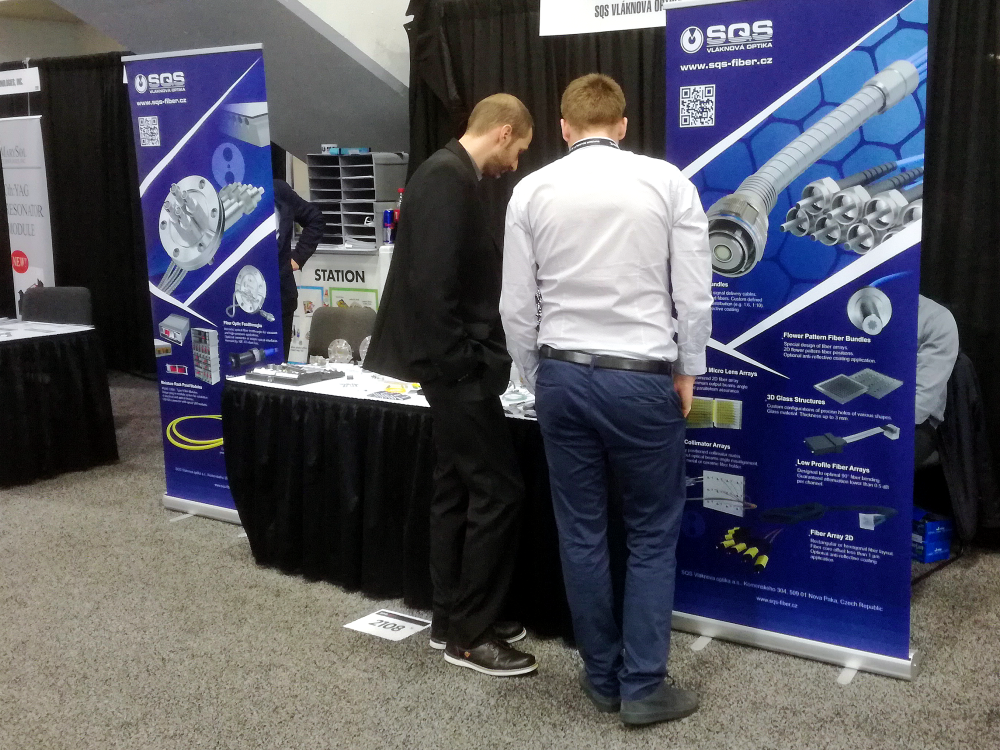

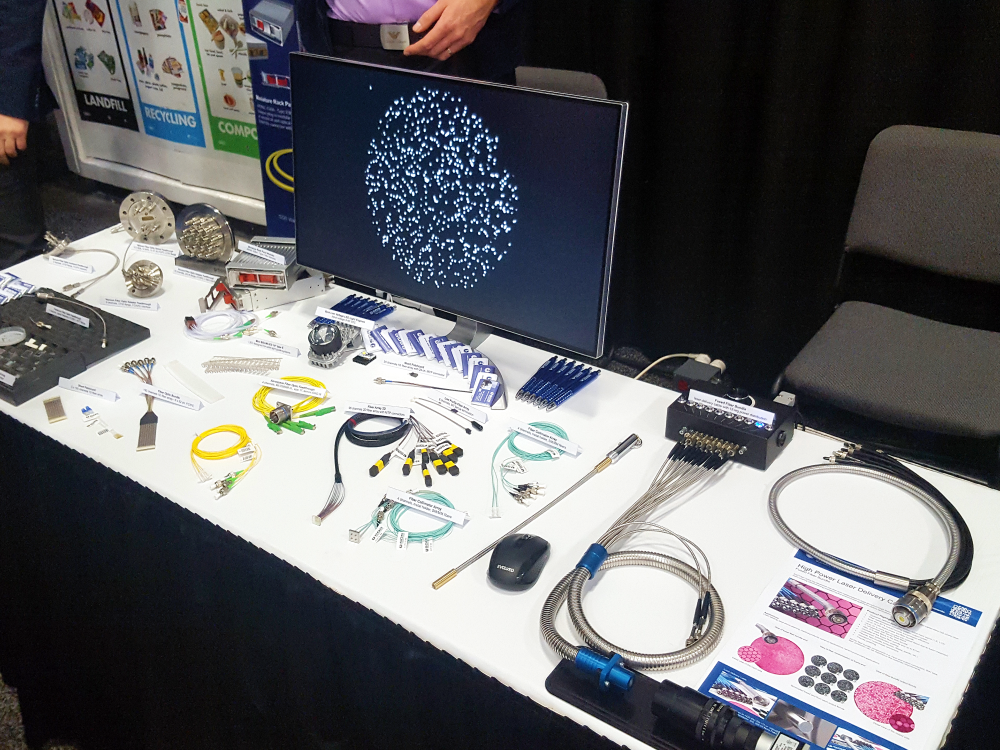

From 5 to 7 February 2019, SQS Fiber Optics will take part in the Photonics West Fair in San Francisco. If you are going to visit Photonics West, do not forget to stop at our stand, we will be glad to welcome you.

From 5 to 7 February 2019, SQS Fiber Optics will take part in the Photonics West Fair in San Francisco. If you are going to visit Photonics West, do not forget to stop at our stand, we will be glad to welcome you.

The SQS presentation will focus on new products coming from our own development. Among our featured products, there are going to be e.g. fused fiber bundles developed for laser delivery cables, various types of 1D and 2D fiber arrays including low-profile solutions designed to connect optical fibers directly to photonic components on a printed circuit board, or a wide range of optical fiber feedthroughs for transfer of optical signals between environments with very high pressure-differences. We will also present a selection of prototypes of mechanical parts that are often a key part of an overall optical or optoelectronic component solution.

SPIE Photonics West is one of the world's largest events focused on optics and photonics. It includes three conferences (BiOS, LASE, OPTO) and two trade fairs (BiOS Expo and Photonics West Exhibition) involving experts and companies specializing in a variety of related technologies from lasers and other light sources, over cameras, optics and high-speed imaging, to optical communications, fiber optic components, equipment and systems.

SPIE Photonics West—The world's largest photonics technologies event, consisting of three conferences and two world-class exhibitions

Presentation of secondary schools and employers takes place from 19 to 20 October 2018 in Masaryk Theater, Jičín. SQS Vláknová optika is also an important regional employer. At SQS you can learn about the company's focus and main activities, the products being developed and produced, as well as the current offer of job opportunities.

Presentation of secondary schools and employers takes place from 19 to 20 October 2018 in Masaryk Theater, Jičín. SQS Vláknová optika is also an important regional employer. At SQS you can learn about the company's focus and main activities, the products being developed and produced, as well as the current offer of job opportunities.

Presentation of secondary schools and employers is organized by the Hradec Králové Region and the Regional Chamber of Commerce.

The main goal of the organizers is:

- to inspire elementary school pupils in choosing a high school,

- to link schools with employers throughout the Hradec Králové region,

- to present a good cooperation between companies and secondary schools.

The event also features a fair of currently available job opportunities.

For more detailed information, please visit http://vybiramstredni.cz/vybiram-stredni/

On Wednesday, September 5, 2018, the Job Fair will be held in the Masaryk Theater in Jičín. Come and see us at our booth! We will be happy to welcome you and talk to you about our company and possible jobs that might be interesting for you.

On Wednesday, September 5, 2018, the Job Fair will be held in the Masaryk Theater in Jičín. Come and see us at our booth! We will be happy to welcome you and talk to you about our company and possible jobs that might be interesting for you.

We are constantly looking for new employees at positions ranging from production workers through technical and administrative to managerial positions in manufacturing, development, technical design, technology, and quality management.

More information about the Job Fair including photos from previous years may be found on the event site https://www.veletrhyprace.cz/jicin4/

SQS Fiber Optics is going to exhibit at the Optatec international trade fair for optical technologies, components and systems in Frankfurt am Main.

SQS Fiber Optics is going to exhibit at the Optatec international trade fair for optical technologies, components and systems in Frankfurt am Main.

The Optatek fair is held on May 15-17, 2018 at the Messe Frankfurt exhibition grounds (Ludwig-Erhard-Anlage 1, 60327 Frankfurt am Main, Germany) and if you are going to visit Frankfurt, we would be glad to welcome you at our stand in the hall 3, stand no. I74.

Optatec provides the optical industry with the world’s most important information, communication and business platform in Frankfurt Exhibition Centre. In co-operation with conceptual sponsors as well as technology and institutional partners SPECTARIS (the German Industry Association for Photonics and Precision Engineering) and the Fraunhofer Institute for Applied Optics and Precision Engineering (IOF), Optatec is presented as an international, high-tech shop window. The focus of the consistently target-group-specific portfolio is on the areas of fibre optics, photovoltaics, LED solutions and safety systems as well as production/medical technology.

The increasing importance of optical technologies is also manifested in questions of energy and material efficiency as well as in such fundamental areas as the conservation of resources and environmental protection, where optical technologies offer practicable and affordable solutions (see https://www.optatec-messe.de/en/

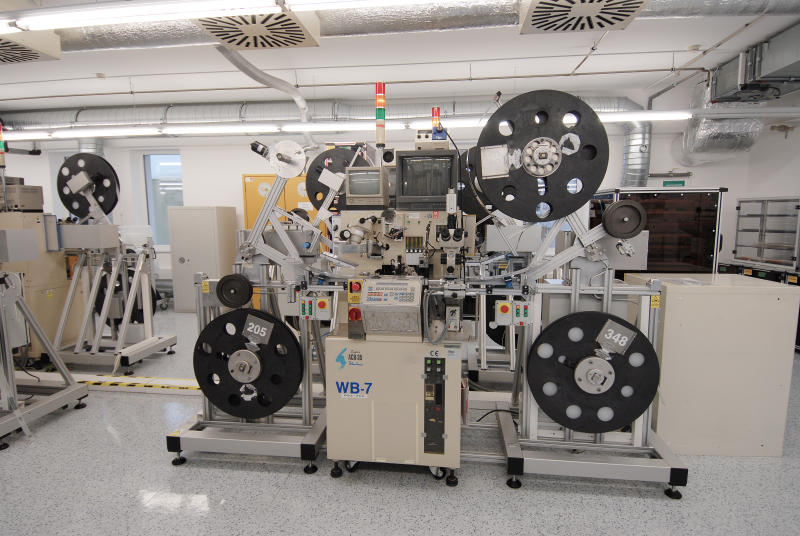

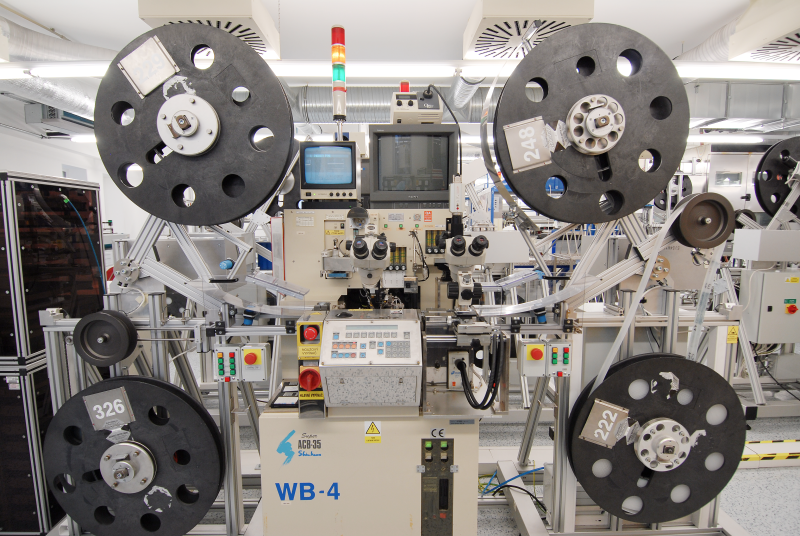

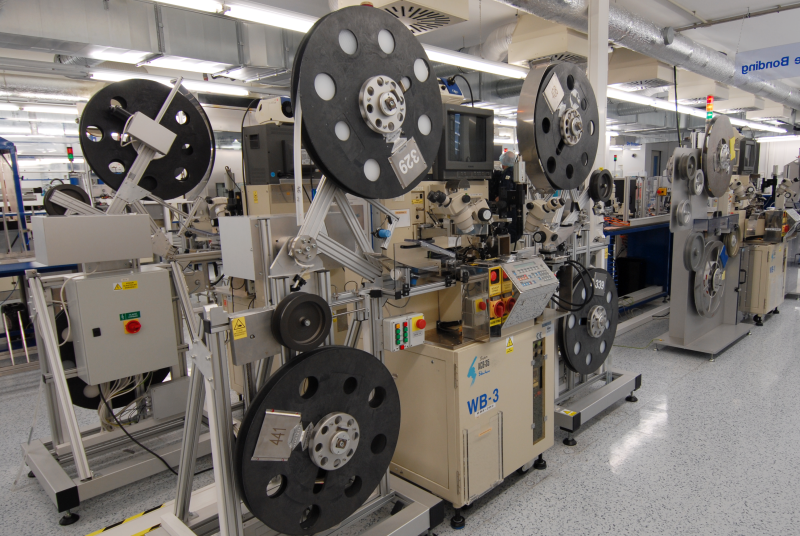

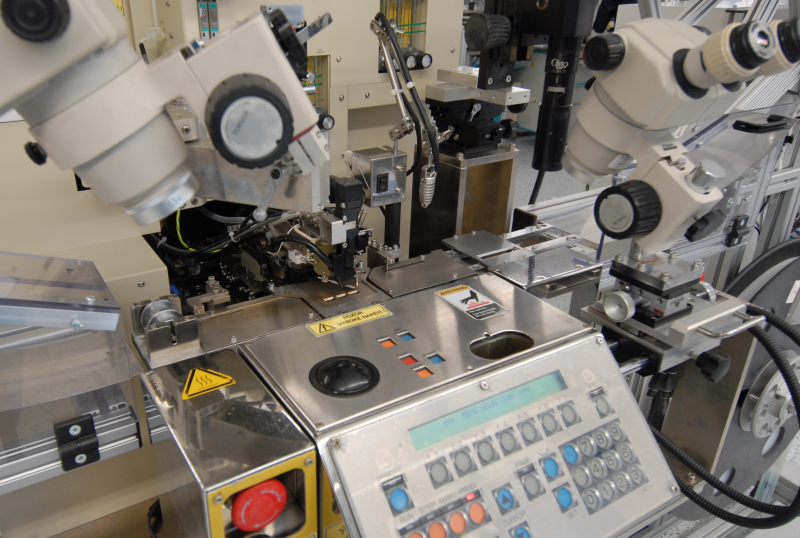

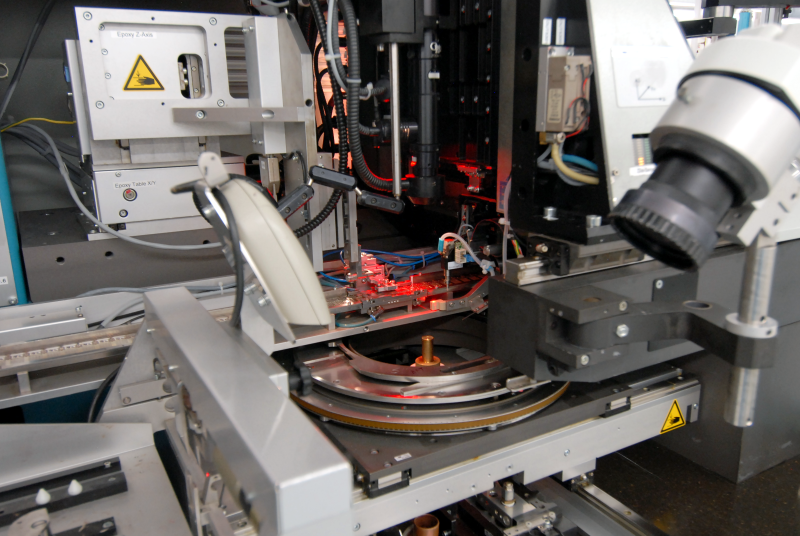

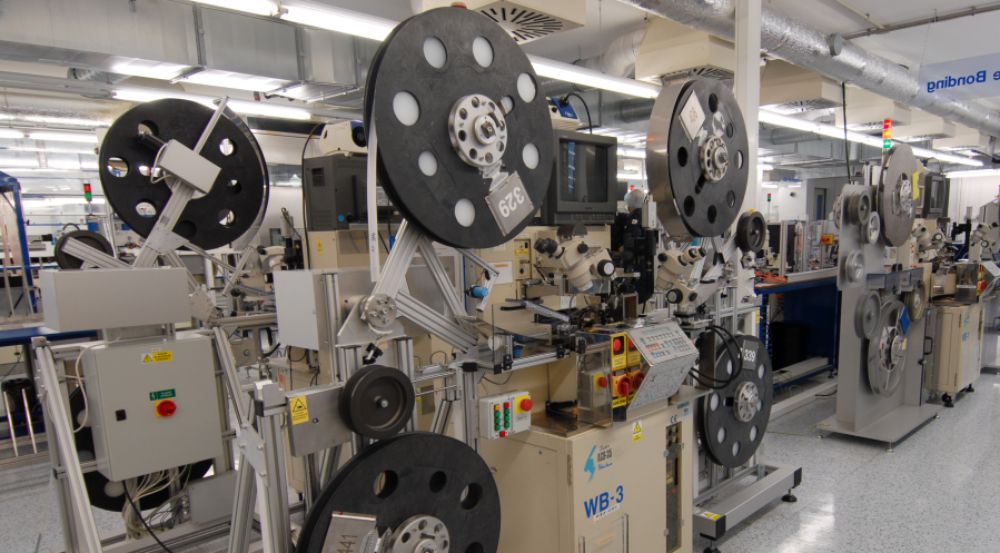

Company SQS Vlaknova optika a.s. Nova Paka offers to sell machines on wire bonding and die bonding of the trademarks Shinkawa and Muhlbauer.

Company SQS Vlaknova optika a.s. Nova Paka offers to sell machines on wire bonding and die bonding of the trademarks Shinkawa and Muhlbauer.

They are special purpose machines Shinkawa Super ACB – 35 and Muhlbauer DB 200WTX7. These machines are used, complete and in working order.

Further in our offer there are spare parts for the special purpose machines.

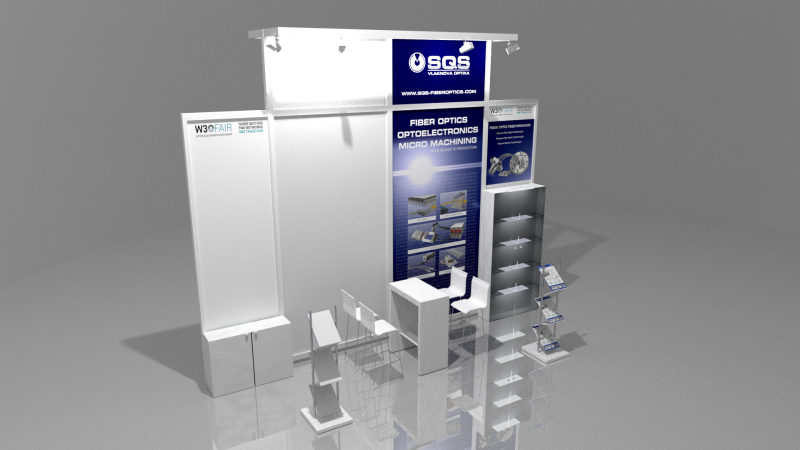

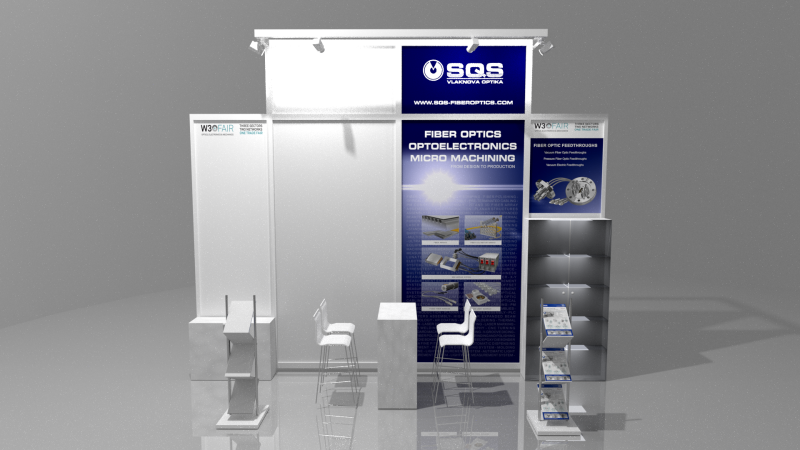

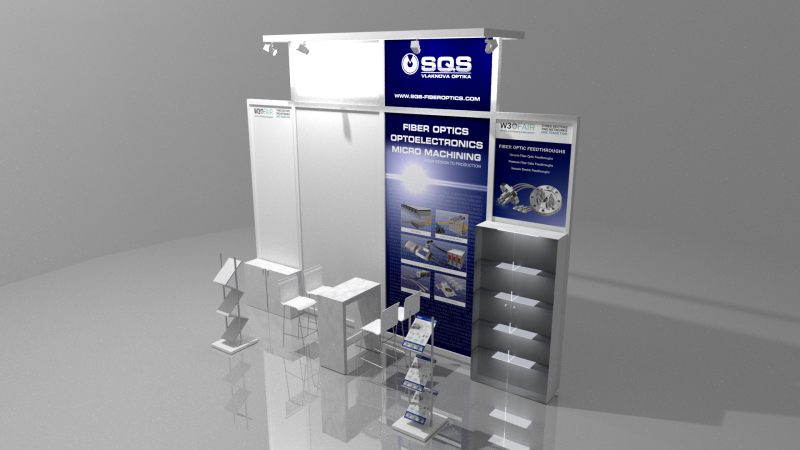

On 21 - 22 February, the W3+ FAIR regional trade show is held in Wetzlar, Germany (near Frankfurt). Wetzlar is a recognized centre for optical technology, in which leading companies from within the expanding mechanics and electronics sectors are also based.

On 21 - 22 February, the W3+ FAIR regional trade show is held in Wetzlar, Germany (near Frankfurt). Wetzlar is a recognized centre for optical technology, in which leading companies from within the expanding mechanics and electronics sectors are also based.

SQS will present mainly its new products combining the expertise and experience of the company in the areas of optics, optoelectronics and precision mechanics. Visitors will be introduced to the SQS product solutions such as fiber bundles for laser applications, fiber arrays with micro-lenses, fiber optic collimator arrays, special optical fiber feedthoughs for vacuum or high-pressure applications, ARINC 836A modular miniature interconnect system, LED light sources.